- Workshop Tools and Workshop Machines India: buy@naugra.com

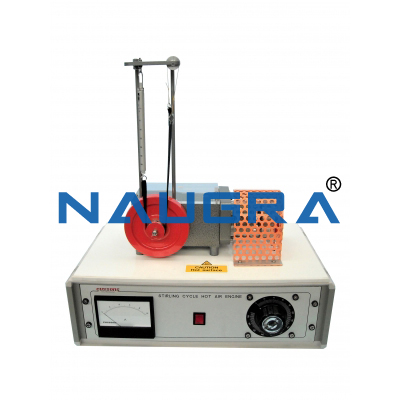

Stirling Cycle Hot Air Engine .

Description of Stirling Cycle Hot Air Engine for Science Lab Equipment Laboratory Instruments Manufacturers, Engineering Lab Equipments Manufacturers

The cycle on which the engine is based consists of two isothermal processes and two constant volume processes (the latter being performed with the aid of a regenerator). The source of heat is provided from a low voltage electric element so that it may readily be controlled and measured. Output is measured by the simple dynamometer supplied. The engine has one working cylinder and a transfer cylinder arranged side by side in open communication one with another but without any intervening valve mechanism. The power cylinder has a single acting piston connected to the crankshaft while the transfer cylinder has a double acting displacer piston and regenerator operated by an eccentric, the phasing of which can be altered in relation to the crankpin of the power cylinder. The optimum phase angle can be determined and rotation can be reversed. The heating element is located at one end of the transfer cylinder, which is made of pyrex glass, so that the element and the transfer piston can be clearly seen. Relatively little information exists concerning the detail design of small hot air engines and this engine was designed from first principles with the aid of a computer to determine the optimum proportions of the various working elements. A variety of experiments can be carried out and the effect on performance of the use of gases of different specific heat ratio can be established. By means of the transparent cylinder the temperature of the element may be seen to fall as heat is extracted from it when the engine starts from rest.

Applications of Stirling Cycle Hot Air Engine:

Cyclic compression and expansion of air

Closed-cycle

Study of Hot air engine

Effect on performance

Use of gases of different specific heat ratio

Temperature differential

Regenerative heat exchanger

Specifications of Stirling Cycle Hot Air Engine:

Stirling Cycle Hot Air Engine with integral power pack incorporating a variable voltage control and ammeter and furnished with prony dynamometer .

For operation on 220/240V, 50Hz single phase supply, other power supplies are available to special order.

Demonstrates conversion of heat energy into work

Suitable for bench top use.

Engine to have one working and one transfer cylinder

Working cylinder to have single acting piston.

Transfer cylinder to have double acting displacer piston

Low voltage electrical element heat source.

Output measured by 0-200 gm spring dynamometer

Integral power pack, incorporating a variable voltage heater control and ammeter.

Complete with hanger and masses