- Workshop Tools and Workshop Machines India: buy@naugra.com

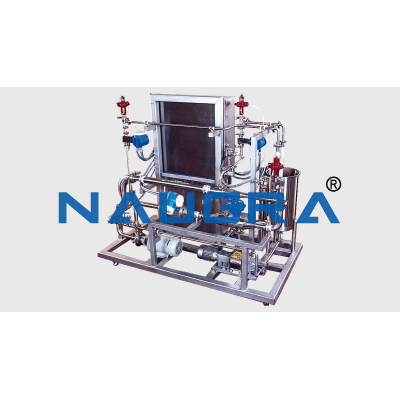

Milk Sterilisation Pilot Plant .

Milk Sterilisation Pilot Plant for Science Lab Equipment Laboratory Instruments Manufacturers, Engineering Lab Equipments Manufacturers

Technical Specification of Milk Sterilisation Pilot Plant

Wheeled framework of AISI 304 stainless steel

Max. feeding: 100 l/h (higher flow rates on demand)

Cylindrical feed tank of AISI 304 stainless steel, mirror polished inside, with capacity of 80 l

Cylindrical tank of AISI 304 stainless steel, mirror polished inside, with capacity of 80 l, for collecting the sterilized product

Gear-type feed pump with body of AISI 316 stainless steel and flow rate of 200 l/h

Electronic frequency variator for feed pump

Feed flow meter of AISI 316 stainless steel, with range of 0 to 100 l/h, accuracy: ± 0.5%

Plate-type milk pre-heater of AISI 316 stainless steel, with exchange surface of 0.6 m²

Sterilization chamber of AISI 304 stainless steel

Vacuum chamber of borosilicate glass, with capacity of 5 l,for reducing milk temperature after sterilization

Liquid-ring vacuum pump, P = 0.7 kW, provided with air/water separator

Plate heat exchanger of AISI 316 stainless steel, for milk cooling, exchange surface of 0.6 m²

Milk Sterilisation Pilot Plant

Semi-Automatic Milk Sterilisation Pilot Plant DIFT146/1

Automated Milk Sterilisation Pilot DIFT146/2

Semi-Automatic Milk Sterilisation Pilot Plant

A Milk Sterilisation Plant that simulates a UHT system with direct steam heating.

The milk is heated and then absorbed water from the steam is removed, followed by rapid cooling of the milk.

Automated Milk Sterilisation Pilot

Plant with SCADA

A Milk Sterilisation Plant that simulates a UHT system with direct steam heating.

The milk is heated and then absorbed water from the steam is removed, followed by rapid cooling of the milk. The plant is supplied with a PID controller and software.