- Workshop Tools and Workshop Machines India: buy@naugra.com

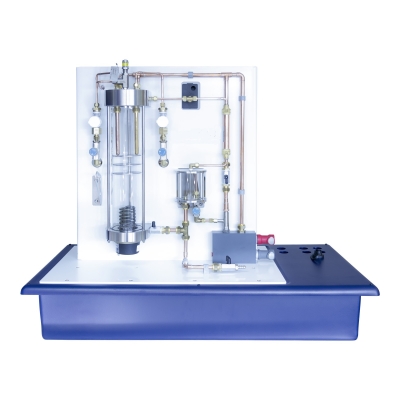

Film and Dropwise Condensation Unit .

Film and Dropwise Condensation Unit for Science Lab Equipment Laboratory Instruments Manufacturers, Engineering Lab Equipments Manufacturers

Although the differences in the modes of boiling heat transfer are generally recognised many students are not aware that two distinct modes of condensation can occur. The Film and Dropwise Condensation Unit is a self-contained bench top unit that allows the investigation of heat fluxes and heat transfer coefficients during the Film and Dropwise Condensation Unit of steam.

The considerable difference between the appearance and heat transfer rates Of Film and Dropwise Condensation Unit are clearly demonstrated. Heat fluxes approaching 1000 kW/m2 can be obtained.

Experimental Capabilities of Film and Dropwise Condensation Unit

Visual observation of Filmwise And Dropwise Condensation, and of nucleate boiling.

Measurement of heat flux and surface heat transfer coefficient in both Filmwise And Dropwise Condensation at pressures up to astmospheric.

Investigation of the saturation pressure/temperature relationship between about 20oC and 100oC.

Demonstration and investigation of the effect of air in condensers.

Demonstration of Daltons Law.

Specification of Filmwise And Dropwise Condensation:

High quality ABS Plastic Panel, having an attractive appearance, and on which the following components are mounted:

1. Steam Chamber: Thick walled glass cylinder with flared ends and seals to nickel plated brass cylinder covers.

2. Condensers: TWO - water cooled - mounted in upper cylinder cover. Dimensions: 12.7 mm external dia. X 90 mm effective length. Specially designed and fabricated from copper and brass, incorporating a heat exchanger to minimise variation of surface temperature.

Dropwise condenser – gold plated.

Filmwise condenser – natural finish.

Each condenser shell is fitted with three thermocouples connected to measure the mean metal temperature and two thermocouples to measure the inlet and outlet water temperatures respectively.

3. Heating Element: Coiled 3 kW electric heating element with thermal protection.

4. Heater Control: Triac control to manually vary heat input from approximately 0.4 to 3.0 kW.

5. Air Extraction System: Air cooler, separator and water jet vacuum pump with the necessary valves