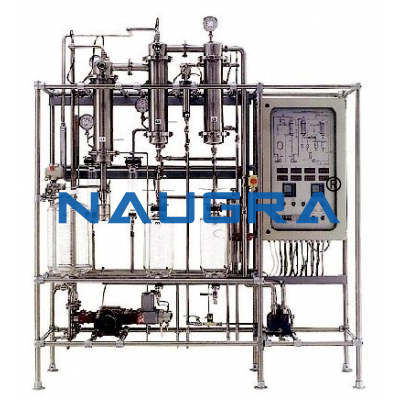

Double Effect Falling Film Evaporation Plant .

Double Effect Falling Film Evaporation Pilot Plant

- Metering pump with a flow rate of 0 to 32 litres per hour and pneumatic actuator

- Feed tank with a capacity of 25 litres

- Tank with a capacity of 10 litres for collecting the concentrated product

- Tank with a capacity of 10 litres for collecting the condensed solvent

- 2x Steam traps

- 2x Graduated tanks with a capacity of 1 litre for measuring the condensate

- Bourdon pressure gauge with a capacity of 0 to 6 bar

- Bourdon pressure gauge with a capacity of 0 to 1.6 bar

- Bourdon vacuum gauge with a capacity of 1 to 0

- Metering pump with flow rate of 0 to 8.5 litres per hour

- 2x Falling film shell-and-tube evaporators, each with an exchange surface of 0.27 m2

- Shell-and-tube condenser with an exchange surface of 1.1 m2

- Tube-in-tube heat exchanger

- Level transmitter, capacitance type with electronic display

- Pneumatic valve for control of the steam flow rate, Cv=0.32

- Calibrated diaphragm with differential pressure transmitter for measuring the steam flow rate

- 12x digital thermocouples with pt100 probes protected by stainless steel shield sleeves

- 12x electronic temperature indicators

- Flow meter with a range of 25 to 250 litres per hour

- Liquid ring vacuum pump of power 0.7 kW equipped with air/water separator and solenoid valve for feed water

- Pipework manufactured from stainless steel

- Electrical control panel in main cabinet

- Emergency stop button