- Workshop Tools and Workshop Machines India: buy@naugra.com

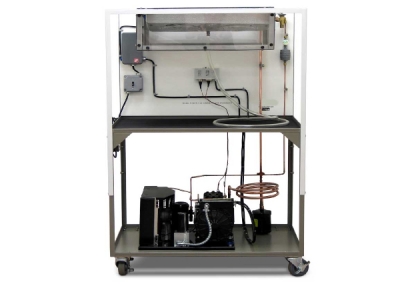

Computerized ICE Plant Trainer .

The The unit enables the students to study the Basic Principals of ice plant cycle within a short period. The test rig is designed for the study of thermodynamics of vapour Compression refrigeration cycle by way of demonstration and experimentation. It has a facility to measure various parameters for experimentation. Ice cans are kept in liquid tank, which is cooled by the refrigerant evaporator. As conventional ice plants take 12-24 hours to complete the cycle, this ice plant is specially designed to demonstrate process of ice formation to be complete within period of 4 hours and hence it is most suitable for laboratory use.

The present set-up has a facility to interface the system with computer, which enables to log the experimental data-using computer. The educational software and data-logging package has been developed for unit.

FEATURES

To study the working of ice plant.

To study the refrigerator circuit.

To calculate co-efficient of performance

SPECIFICATION

Compressor: Hermitically sealed compressor, Kirloskar make.

Tank: The inner tank shall be fabricated out of stainless steel

Condenser: Air cooled compatible to compressor

Condenser Cooling Fan: Compatible capacity with permanent lubricated motor.

Pressure Measurement: Pressure Transmitter- 2 Nos.

Temperature Measurement: Temperature Transmitter- 6 Nos.

Evaporator: Made of Stainless Steel, Insulated with ceramic wool/puff.

Expansion Device: Capillary Tube Compatible capacity.

Energy Measurement: By Energy meter

Safety Control: overload and over current protectors for compressor and Time delay circuit.

Measuring ranges

Differential pressure: 0…1000Pa (air)

Flow rate: 12…360L/h (water)

Temperature: 2x 0…50°C, 3x 0…100°C

Rel. humidity: 10…100%

Required for operation

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase