- Workshop Tools and Workshop Machines India: buy@naugra.com

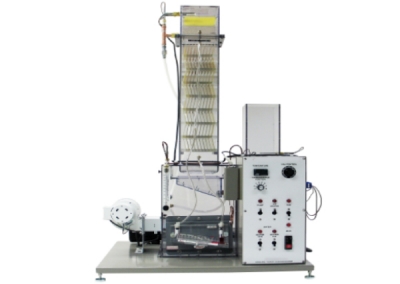

Computerized Cooling Tower Test Bench .

The examines the main components and principle of a wet cooling tower with forced ventilation. Water is heated in a tank and transported by a pump to an atomizer. The atomizer sprays the water to be cooled over the wet deck surface. The water trickles from the top to the bottom along the wet deck surface whilst air flows from the bottom to the top. The heat is transferred directly from the water to the air by convection and evaporation. The evaporated water volume is recorded. The airflow is generated by a fan and adjusted using a throttle valve.

The cooling column is transparent allowing clear observation of the wet deck surface and the trickling water. Interchangeable cooling columns enable comparative studies. Software for data acquisition via USB.

All important process parameters are recorded (volumetric air flow rate, temperatures of air and water, air humidity, water flow rate). The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included. The changes of state of the air are represented in an h-x diagram.

SPECIFICATION

Cooling column

Specific surface of the wet deck surface: 110m2/m3

Cross-section: 150x150mm

Volumetric airflow measurement via orifice: Ø 80mm

Heater, adjustable in three stages:

500W

1000W

1500W

Thermostat: switches off at 50°C

Fan

Power consumption: 250W

Max. Pressure difference: 430Pa

Max. Volumetric flow rate: 13m3/min

Pump

Max. Head: 70m

Max. Flow rate: 100L/h

Tank for additional water: 4,2L

Measuring ranges

Differential pressure: 0…1000Pa (air)

Flow rate: 12…360L/h (water)

Temperature: 2x 0…50°C, 3x 0…100°C

Rel. humidity: 10…100%

Required for operation

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase